Sheet Metal Deep Drawing

TECHNICAL DESCRIPTION

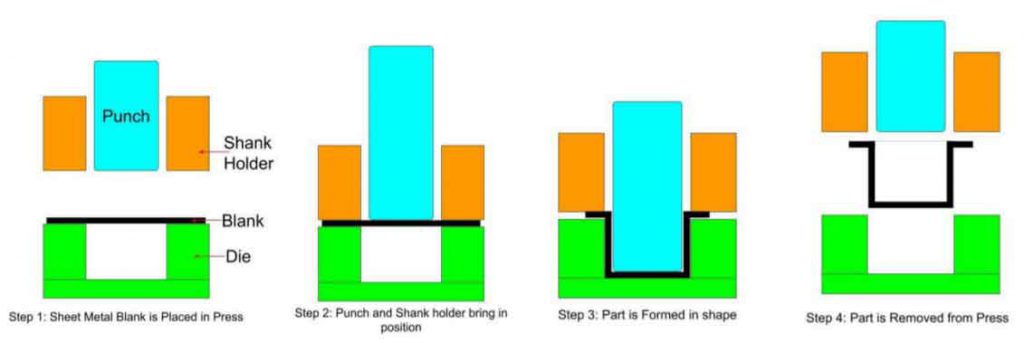

The deep drawing process is carried out in different ways – the method of process being determined by the complexity of the shape, depth of draw, material and thickness. In stage 1, a sheet metal blank is loaded into the hydraulic press and clamped into the blank holder. In stage 2, as the blank holder progresses downwards the material flows over the sides of the lower die to form a symmetrical cup shape. In stage 3, the punch forces the material through the lower die in the opposite direction. The metal flows over the edge of the lower die to take the shape of the punch. In stage 4, the part is ejected.

The tonnage of the press is determined by the tooling. Anything up to 1,000 tonnes may be applied to shape a long or large profile.

INTRODUCTION

Cold metal pressing is known as ‘deep drawing’ when the depth of the draw is greater then the diameter (sometimes when the depth is only 0.5 times greater than the diameter). This process can be used to produce seamless sheet geometries without the need for any further forming or joining operations.

There is a limit to how much sheet metal can be deformed in 1 operation, and the type of material and sheet thickness determine the level of deformation. A variety of techniques are therefore used to produce different geometries. Simple cup-like geometries can be produced in a single operation, while very deep parts and complex geometries are made using progressive dies or the reverse drawing technique. Reverse drawing presses the sheet material twice in a single operation, inverting the shape after the first draw. Operating in this way accelerates cycle time and reduces the number of progressive tools required.

TYPICAL APPLICATIONS

The most common products manufactured by deep drawing include beverage cans and kitchen sinks. However, these techniques are also used to produce a variety of items in the automotive, aerospace, packaging, furniture and lighting industries.

QUALITY

Surface finish is generally very good, but depends on the quality of the punch and die. Wrinkling and surface issues usually occur around the edge, which is trimmed post-forming.

DESIGN OPPORTUNITIES

Various sheet geometries can be produced with the deep drawing, including cylindrical, box-shaped and irregular profiles, which can be formed with straight, tapered or curved sides. Undercuts can be achieved with progressive dies or perpendicular action in the drawing press. However, this will greatly increase the tooling costs.

COMPATIBLE MATERIALS

Deep drawing relies on a combination of a metal’s malleability and resistance to thinning. The most suitable materials are steels, zinc, copper and aluminium alloys. Metals with high resistance to thinning are less likely to tear, wrinkle or fracture during processing, so thinner sheet material can be used to start with.

COSTS

Tooling costs are very expensive because the punch and die have to be engineered to precise tolerances. Progressive tooling, required to produce complex or especially deep parts, increases costs considerably for this process. Cycle time is quite rapid but depends on the number of stages in the pressing cycle, while labor costs are moderate due to the level of automation.